Next to these big bags are stacked palettes full of Turkish hazelnuts – a delicate commodity, as the blossoming hazel trees in Trabzon suffered a frost in spring 2014, doubling the price of the year’s harvest. A little further on, boxes of almonds imported from California are piled up on top of one another. These are the raw materials of Camille Bloch in the same plant where production began in the Saint-Imier valley 86 years ago.

In the first production hall, German-made machinery, some of it not so new but still gleaming, turns incessantly. This is where the roasting and grinding of the beans, hazelnuts and almonds takes place. It gives off a sweet, roasted aroma. The view from the large windows looks out over meadows. The fields extend to the edge of the forest running along the Saint-Imier valley and there is a real sense of isolation even though we are just 20 minutes away from Biel by train.

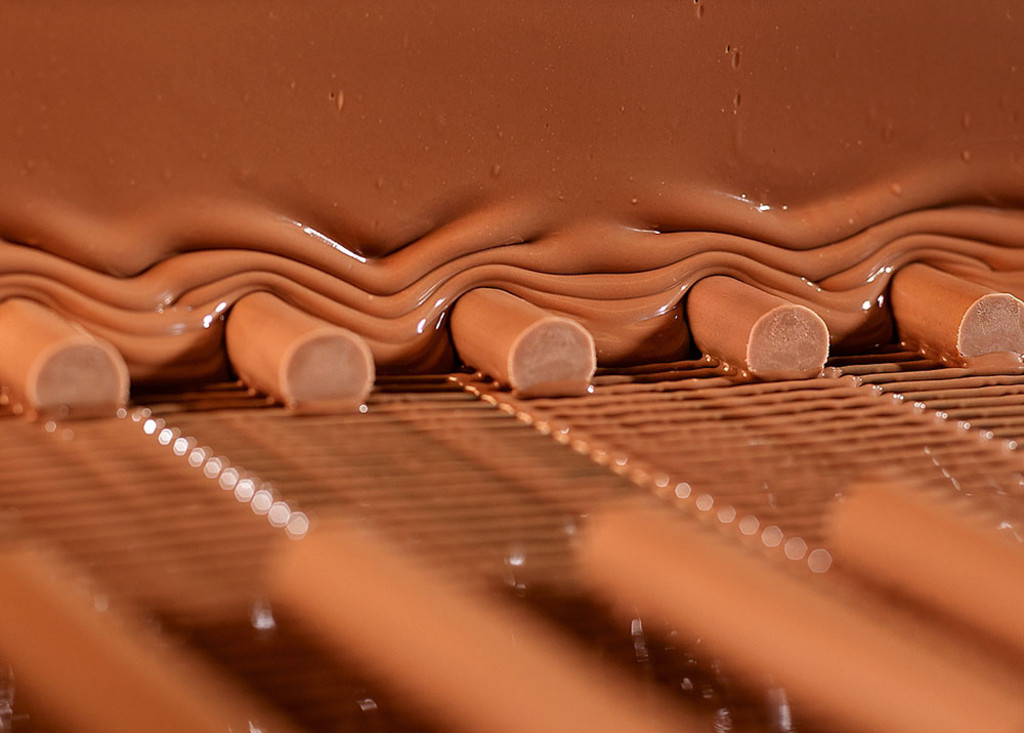

The raw materials used to make Ragusa and Torino chocolate bars are then transported by pipeline towards the plant’s main building. Here, the moisture is removed from the cocoa and it falls as powder into the bottom of large heating tanks. It is now transformed into a paste. After passing through the “kitchens” on the floor above, the mass re-emerges with cocoa butter and powered milk added to the mix. Enormous mixers – known as “conches” – knead the paste to turn it into almond or hazelnut praline. “The fillings are our speciality,” explains company spokesperson Regula Gerber.

The heat on this floor is tropical and you cannot hear yourself speak for the noise. Torino bars, thousands of bars filled with almonds and hazelnuts, advance along the production line 20 abreast. Passing through chocolate rollers, the bottom of the pralines is covered with chocolate, before they receive an overall topping. The line then goes through a cold section to solidify the bars before they are cut and boxed by Camille Bloch employees. Their heads covered in paper hats, there are around a hundred staff – operators, food product specialists, engineers, electricians and assistants – working for the Bloch family on production and machine maintenance. According to the management, the automation of processes will see the number of workers focussing on repetitive tasks fall in the future. The work will shift towards more complex procedures because, chocolate or not, Camille Bloch is still an industrial concern.

stéphane herzog is an editor with the “swiss review”

![[Translate to en:]](/fileadmin/_processed_/9/e/csm_maggi-flasche-geneigt_d99b6f4bac.jpg)

Comments